Service

+44 1371 878 802

14a Oak Industrial Park

Chelmsford Road

Great Dunmow

Essex CM6 1XN

Phone: +44 1371 878 800

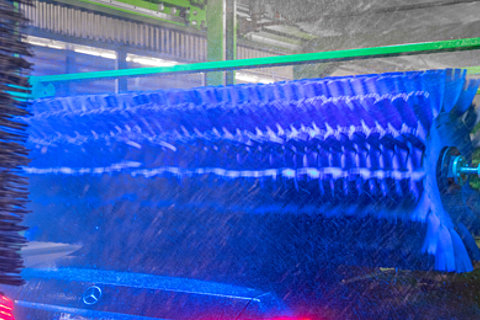

"A good friend operates two conveyor tunnel car wash systems equipped with WashTec technology," says Hima Bashkim, operator of the car wash on the western outskirts of the university city of Aachen. "I also looked at solutions from other manufacturers. In the end, I decided in favour of WashTec because they make more out of less," he says, explaining the main reason. "The washing brushes get right up to the vehicle and do so again on the return pass." In fact, WashTec's linear technology intensifies the vehicle wash, as linearly travelling roof and side brushes remain in contact longer and evenly with the vehicle surfaces. In addition, the washing brushes are fed in precisely by electronic impulses. They even accelerate for a moment before they swivel in from the side to the centre when level with the rear of the vehicle. The innovative linear technology saves more than one metre in chain length. And "the way the system is controlled allows you to get the maximum out of it," praises Hima Bashkim WashTec.

Back in 2013, the committed car wash entrepreneur started up a modern car wash with WashTec technology in Würselen, just ten kilometres away, where he also deals in new and used cars and runs a motor vehicle workshop. "The idea of setting up the first car wash was relatively spontaneous. At that time I had already decided to operate a car dealership on a main road in Würselen," says Hima Bashkim. "We worked at the Würselen site on Krefelder Strasse for about two years until we noticed that there was no good washing facility there for cars. I talked to some friends who were familiar with car washes."

Hima Bashkim explains why he first planned and then realised a second car wash on the site at Weststrasse 36 as follows: "I used to live where we are now in Aachen. There is no car wash here. The nearest car washes of this kind are located in the east of the city and are therefore far enough away as competitors." Hima Bashkim finally decided to buy the site in May 2017. His commercial bank agreed when he presented his business plan to the bank's employees, making it clear that there is a demand "here". He commissions a local civil engineering company to prepare the site in such a way that a modern, customer-friendly car wash business with all the typical cleaning and care services can be established.

The WashTec sales consultant took on the task when it became clear that, after the car wash in Würselen, WashTec technology would once again be the measure of all things. He recommended a SoftLine² conveyor tunnel system to the operator. "Together, we considered what technology is needed to wash about 120 vehicles in an hour. Then we decided to build the car wash according to the semi-express principle." The background for this was not to completely dispense with the pre-wash, but to carry it out "minimally" on a small scale. This means, we pre-spray the vehicles, especially the very dirty areas, but no more than this." The employee then waves the vehicles onto the plastic conveyor belt. It can accommodate tyres up to 37 centimetres wide. The belt is designed to protect the tyres as much as possible. The above-ground height measures six centimetres. Hima Bashkim advertises with "zero damage to the rims" to the car wash customers.

The automatic vehicle wash greets the customers with "textile wash" and, after a few centimetres of conveyor belt progress, starts the active foam application, which hisses from the horizontal and vertical nozzles of the bright green Smart - LED entrance gantry. The wheel washer, which travels along for more than one metre, pushes its disc brushes in pairs against the front and rear wheels in order to rotate and clean all rims very thoroughly. The two high-pressure BPS spot spray systems that follow immediately compensate for the express pre-wash. Four BPS spot spray nozzles rhythmically oscillating up and down perfectly clean the horizontal and vertical vehicle surfaces in harmony with the rotating high-pressure washer. Its TurboNozzles powerfully clean sills and rims a second time. Linear-technology roof and side brushes intensify the mechanical washing process before the vehicles are transported through "the illuminated ShineTecs® arch and reach the care station, where the best performance high-gloss foam polish with paintwork 'repair function' is gently massaged in by three textile brushes. SofTecs®, which not only cleans vehicles but also cares for them, is "much better than other washing materials," says Hima Bashkim with conviction. He also says: "When it came to drying, we opted for two plus two. The good solution involves two roof and two side nozzles." The textile brush dryer, which follows the blower dryer and moves along linearly, ensures virtually drip-free vehicle drying. A revolving cloth dryer equipped with 36 cloths perfects the drying result. The countdown traffic light counts down every second until an arrow gives the car wash customer the signal to start. "Most customers haven't got a clue what is means. It is probably positioned a little too far away on the passenger side," admits Hima Bashkim. At the end of the 65 metre long wash bay, the vehicles turn sharply to the left and head for one of the 27 vacuum cleaner stations and use one of the four mat cleaners. Both services are free of charge.

Customers driving to the Hima car wash centre in Aachen reach the entrance of the wash and vacuum cleaner bay via an approximately 50 metre long forecourt entrance. Due to the somewhat unfavourable location, the committed, fun-loving car wash operator advertises with an A5 flyer that is attractively designed on the front and back, for example, on which he offers "expert interior valeting and polishing" in addition to the trio of wash programmes "Basic care", "Gloss care" and "Premium care". Prepaid cards that can be topped up are assigned bonus schemes. He uses the advertising space on shopping trolleys in supermarkets and still holds on to a very special idea. "At the site of my new car wash in Aachen, I would like to have a balloon attached to a rope floating at least 40 metres in the air to show that we are right here. The aviation authority will probably have difficulty approving my request," he assesses the situation quite realistically. Well, maybe you'll soon see WashTec high above the city.

"A good friend operates two conveyor tunnel car wash systems equipped with WashTec technology," says Hima Bashkim, operator of the car wash on the western outskirts of the university city of Aachen. "I also looked at solutions from other manufacturers. In the end, I decided in favour of WashTec because they make more out of less," he says, explaining the main reason. "The washing brushes get right up to the vehicle and do so again on the return pass." In fact, WashTec's linear technology intensifies the vehicle wash, as linearly travelling roof and side brushes remain in contact longer and evenly with the vehicle surfaces. In addition, the washing brushes are fed in precisely by electronic impulses. They even accelerate for a moment before they swivel in from the side to the centre when level with the rear of the vehicle. The innovative linear technology saves more than one metre in chain length. And "the way the system is controlled allows you to get the maximum out of it," praises Hima Bashkim WashTec.

Text / Pictures: Bernd Fiehöfer